Excel Engineering Calculations have both check and design based. Design Calculation Using Excel Spreadsheet.

Mitcalc Shafts Calculation Standaloneinstaller Com

Coupling is a mechanical device which used widely in many big and small scale industries.

. Fundamentals Of Machine Component Design - Juvinall. 207006 x 10 3 N-mm 70Mpa N-mm 2 x π x d 3 16. Excel Engineering Calculations includes many calculation tools in the field of technical industrial engineering.

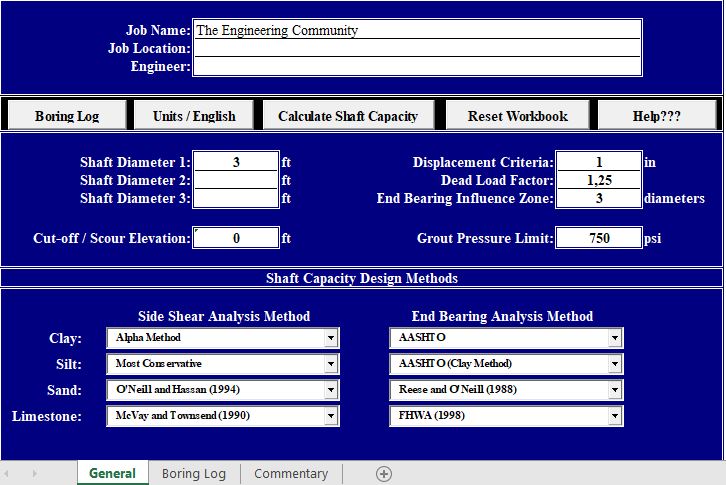

- Simple definition. Shaft 1-2-3 was developed in conjunction with a Florida Department of Transportation FDOT study to help quickly determine the. Shaft Poisson ratio Shaft modulus E GPa Shear modulus G GPa Undercut design torsion stress MPa Fillet design torsion stress MPa Polar I at fillet shaft diameter mm4 Polar I at undercut shaft diameter mm4 Fillet stress concentration factor Kt Undercut stress concentration factor Kt shaft_torsionxls To help design shafts in torsion.

ShaftDesigner is a CAE shaft calculator software for high-quality marine propulsion fair curve shaft alignment bearing bush calculations torsional vibration analysis axial vibration analysis. Calculate the torque on the shaft from power Step 2. Broms Soil Parameter Estimation.

Power Transmission Shafting Straight and Curved Beams Couplings Power Screw Actuators Hydraulic Actuators-Pumps-Motors. Instructions are included in the files. MITCalc Download Buy.

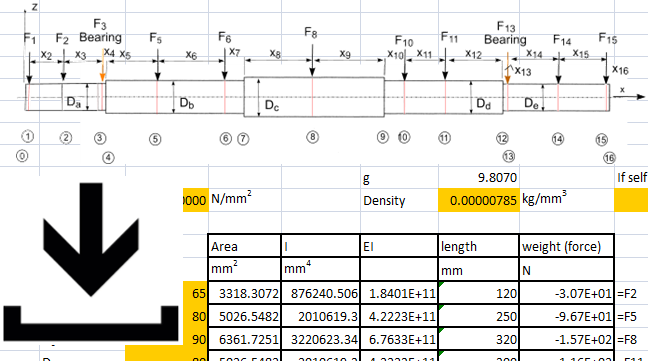

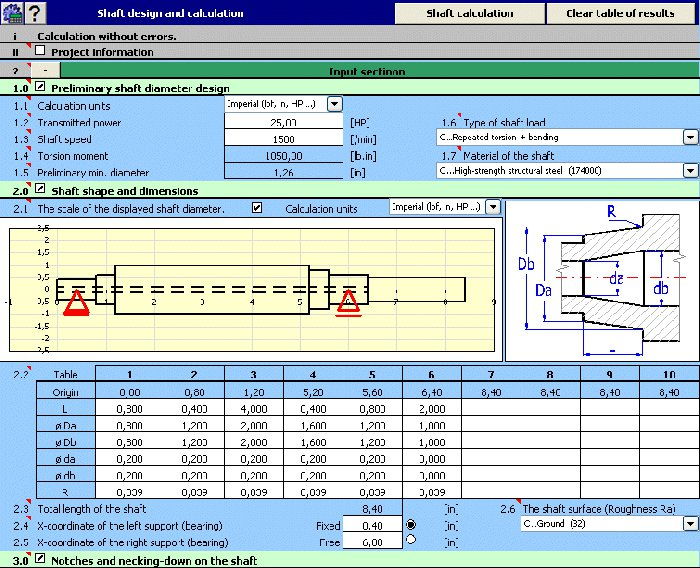

Application is developed in MS Excel is multi-language supports Imperial and Metric units and solves the following main tasks. This 8 hour online course defines the design equations of several basic machine components resulting in Excel print-outs of design parameters and calculated results. If necessary combine the forces.

Download ODOTs drilled shaft foundation design spreadsheets below. The effect of stress concentrations is negligible. MITCalc - Shafts Calculation v120.

90 rows Shaft Design. He a lso has an Excel Spreadsheet model that is available for student use. Machine Design Excel Calculations.

Shaft Design Problems Step 1. The calculation is designed for geometrical designs and complex examinations of shafts. Design the shafting concept perform shaft alignment and analyze propulsion vibration efficiently with ShaftDesigner.

Strength of Materials for Combined Stress in unsymmetrical Bending Case. The shaft is straight. Design of Shafts 1.

Bearing Application and Specifications. The calculation is designed for geometrical design and complex strength check of shafts. Drilled Shaft Foundation Design Spreadsheet.

Up to 24 cash back Shaft designxls. Shaft Stress Calculations Shaft 1 Diameter38 Material. The Shaft Calculation Software.

Find the torsional stress in the shaft Step 3. This location is for Registered Users Only. Simple definition of installed shafts including hollow ones.

T Max 207006 N-m. It guides you quickly and accurately to different design of components fix to any technical glitches or to perform any calculation of any engineering point without requiring any specific expert knowledge. A shaft between self-aligning bearing A and B is loaded through belt forces applied to a central sheave.

2004 provides a solid treatment of shaft design fairly early in his text. Options of definitions of necking-down recesses grooves and calculation of the relevant coefficients of stress concentration. D 3 150687075 mm.

RameshSingh Introduction Torque and Power Transmission Most of rotary prime movers either motors or turbines use shaft to transfer the power Bearings are required for support Shaft failure analysis is critical 2. Engineering Design Info. τ xy Shear stress in xy plane Nm 2 ω angular velocity radss θ angular deflection rads Assuming the shaft is made from a ductile material the failure criteria applicable is the Maximum Shear Stress Theory MSST criteria.

Calculate the loads coming from gears belts or chains Step 4. A Determine and make a sketch showing the stresses acting on the top and side elements T and S. 3D solid modeling has.

It includes different analysis methods for sand clay silt and limestone. SkyCiv offers a wide range of Cloud Structural Analysis and Design Software for engineers. The software solves the following tasks.

Strength of Materials for Beam Shaft Design and Analysis Case Study 2. The case study in engineering mechanics vibration machine design and others will be discussed in this paper. As a constantly evolving tech company were committed to innovating and challenging existing workflows to save engineers time in their work processes and designs.

August 19 2020 Agency. Many of the concepts one learns in a two course sequence in machinery design culminates in the design of powe r transmission shafts and supporting elements ranging from various drives supporting. The case study in this paper is listing below.

Shaft 1-2-3 is a macro-driven Excel spreadsheet which utilizes VBA programming for calculating ungrouted and grouted drilled shaft capacities. Calculate the bending moment due to the acting forces. Shaft Power Geometry Calculate Shaft Diameter Left side shaft diameter SD1 Right side shaft diameter SD3 Center shaft diameter SD2 Torsional shear stress Sxy AT POINT B Max shear stress at B Sxymax Max shear stress Sxy F1 F2 Simply supported edges f K 2πDgwr4 Fixed edges f Balancing Rotating Shafts.

Calculate the bending stress in the shaft. This is very relevant to ductile metals. The shaft material is homogeneous and perfectly elastic.

Perhaps you need to login or register. 1045 Steel Yield Strength S y 530 MPa Ultimate Strength 625MPa Max Stress o The shaft is keyed for a 332 key thus a close approximation for the actual yield strength is ¾ the materials yield strength Keyed Yield Strength398 MPa o Loading is comprised of three components. From this maximum operating torque we can find the shaft diameter with the above equation.

Helps in the design of shafts that are to undergo. The maximum torque that can be operated on the shaft T Max 207006 N-m. The weights of the shaft and sheave are negligible.

D 5319 mm.

Shaft Calculation And Design Mitcalc 04 Youtube

Roymech Calculating Shaft Deflections

Shaft Capacity Calculation Spreadsheet

Calculation Of Shafts According To Din 743 Mdesign Shaft

Design Calculation Using Excel Spreadsheet Download Scientific Diagram

Shaft Deflection Engineersfield

Microsoft Excel Design Tool With Spread Sheet For Shaft Design Of The Download Scientific Diagram

0 comments

Post a Comment